I love it when a camper plan comes together

I’ve recently had the pleasure of 8Ball asking me to photograph the process of turning my Volkswagen T6.1 Highline panel van into a fully-fledged, all-singing, all-dancing camper van. I say lucky, as most folk might not want to see their pride and joy have everything ripped out of it, holes cut in it, and then see it all being put back together. But this was my task: to capture this process, and I found the whole thing very interesting from start to finish.

I have written a previous blog on this being my third van 8Ball has made for me, so it might be worth going back to that blog and reading it before this if you haven’t already.

I drove my van into the 8Ball conversion centre on a sunny July morning. After meeting with Colin and Mike, owners of 8Ball, they thoroughly checked over my van to assess its condition and to make sure it is delivered back in the same condition I dropped it off in. We had a quick check over everything we had agreed on to design my van, and we were all set!

Next, the hard-to-watch bit commenced. The van got totally stripped inside and driven into the huge conversion centre to start its journey from panel van to camper van.

You can see how organised the guys at 8Ball are; they have made the conversion process as efficient as possible. Each of the guys has their own specialisation and work bay. The van goes around the bays and has the work done in that bay before moving onto the next bay.

The first bay is Alex’s bay; Alex is Colin’s son, he cuts the van up, ply lines it, insulates it and carpets the interior walls with a material called Vetrim

He expertly cuts the roof off and the window holes out before fitting windows back in, fitting a new Austops roof with a deluxe bed, and then very impressively, he quickly carpets the whole inside of the van with virtually a single piece (to ensure there are no unsightly joins) of Vetrim. I went for a dark grey inside, but there’s a full selection of colours to choose from for the Vetrim interior carpet. It’s amazing to see how much work gets done in this bay and how far the panel van has come just from getting windows a roof and looking sleek inside. It has lost the feel of being a work van and is now basically a day van.

I opted for my Rib seat to be on rails allowing it to move back and forth within the van, (I will talk about what a game changer this is in my next blog ‘Van Life in the Hebrides’ where I take the van on it’s maiden voyage through the Hebrides.) The rails are also fitted by Alex in this bay

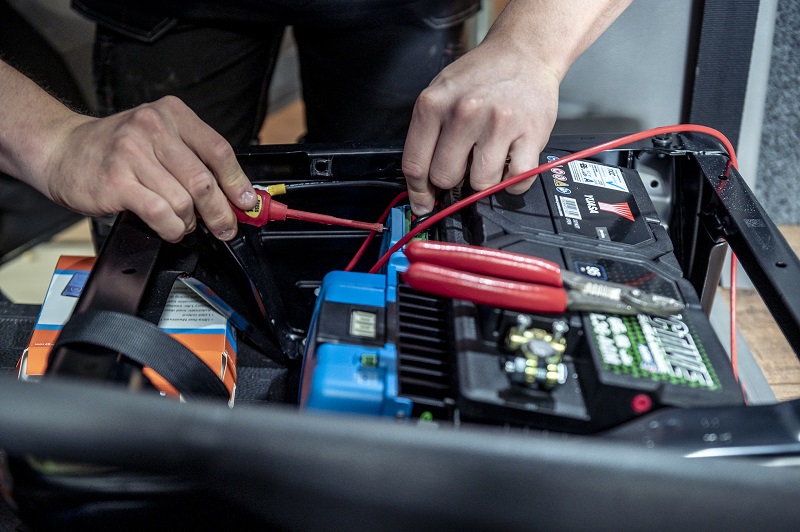

Next, the van goes onto Colin’s bay, where he fits all the van’s electrics, solar roof, leisure battery, fixings for the electric hook up (very neatly placed under the van so an outside plug doesn’t ruin the look of the clean lines of the van), and fixings for the internal plugs, USB sockets, lights, fuse box, and the van’s control panel for all of these. Seeing this process and what actually goes on to create a well-thought-out and functioning van really is impressive.

Next, we have the carpentry bay. Mike, the other owner, and Pud (taken on as an apprentice 10 years ago) work in this section. The carpentry bay is set next to all the woodwork machines to maximise efficiency. Between them, they put the cupboards together and get them in at jaw-dropping speed, communicating and working together like a well-oiled machine. It was a joy to watch these two craftsmen expertly fitting the cupboards and floor, bringing the interior of my van to life.

Next in went the plumbing for the gas cooker and the sink, independently checked and approved. Pud then assembles and fits the RIB bed, and in no time at all, I have a fully working camper van. The whole van then goes through a quality-checking process by another member of the 8Ball crew who hasn’t worked on the van to ensure they have a non-biased check on the work carried out.

This whole process was a privilege and joy to watch. To see a bunch of experienced guys working and communicating very efficiently together to get a job done to the absolute best of their ability with a real care for the final outcome they produce. As I’ve had vans created by 8Ball before, I knew the quality of the vans produced, but now, seeing this process, I know how unbelievably detailed and thorough they have to be to create this kind of quality consistently over the last 20 years.